The Greatest Guide To Omaha Warehouse

Wiki Article

Omaha Warehouse - Questions

Table of ContentsWarehouse Omaha Things To Know Before You BuyThe Omaha Warehouse StatementsFacts About Omaha Warehouse RevealedFascination About Nebraska Warehouse6 Simple Techniques For Omaha Warehouse

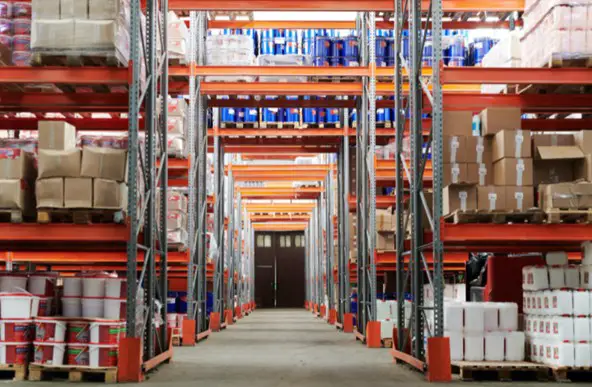

You may like an extra commercial place for your service. In this case, getting a storehouse can be useful for organizations because it indicates that you'll be bordered by other companies that can supply corresponding product and services, or have framework needed to help your company run more efficiently.Storehouses are additionally advantageous because they're commonly made out of solid products like concrete and also steel. This makes them far more long lasting than various other sorts of industrial buildings, such as office complex constructed of wood framework building and constructions. This suggests that they will certainly have the ability to stand up to the deterioration of hefty equipment and also devices, in addition to harsh weather, better than other kinds of structures.

If you need to store huge devices or inventory, you can conveniently do so by segmenting off sections of the inside with wall surfaces or partitions - warehouse Omaha. Or, if you need workplace area for your company, you can rent out areas of the stockroom to lessees. Last but not least, stockrooms use adaptability as well as can be utilized for storage, production, office spaces and also even more.

Omaha Warehouse Fundamentals Explained

If you start out utilizing your warehouse for storage space yet after that need office space in the future, chances are good that you'll be able to transform component of the interior right into workplaces without any type of major remodellings. While buying a storage facility has many benefits, it's not the ideal option for every business. Omaha warehouse.One alternative that you may want to take into consideration is renting space in a commercial park. This can be an excellent choice for businesses that require to be located near various other organizations however do not always need a great deal of room. Industrial parks normally have a range of different sorts of companies, so you'll be able to locate corresponding services located nearby.

Storehouse monitoring interconnects several terms as it is a chain of activities to relocate goods from storage facility to finish consumer on time. To understand what WMS is as well as what features of the stockroom management system are, allow's go deeper into some of the essential stockroom monitoring tasks.

The Best Guide To Omaha Warehouse

Plus, the receiving reports together with conformity to order are put together. Putaway eliminating the material from the location of receipt (the dock), transferring the product to a storage space area, and after that relocate to a determined area. Additionally, it consists of tracking the lincoln storage movement and also time, when the material has actually been placed.Packaging offers with the protection of items. That is packaging them and preparing a container for delivery. Replenishment is moving inventory from second storage locations into taken care of storage space places. Delivering involves the tasks of product packaging, marking, considering, and packing goods for shipment. From the supplier, raw materials take a trip to the enterprise storehouse.

Once the product prepares, it stays in the stockroom of a firm that created it. What's more, products might get to thousands in numbers, so they need to have a barcode or RFID tags that can be scanned. Workers get orders from stores. So, these orders need to be approved, details gathered as well as showed within WMS.

The Buzz on Nebraska Warehouse

And also secondly, to get to better consumer contentment as well as be affordable on the market. Learn more: develop a custom ERP software program for delivery What are the benefits of storehouse administration system? Storehouse management software application has seen a great deal of improvements considering that the application of AI, the Internet of Things as well as robotics, brand-new integrations, and automatized processes.

The system can compute and specify an accurate strategy when and also which items we will obtain firstly as well as which ones will certainly offered. Precise forecasts permit sales to increase and avoid loss of money basing supply on existing sales and also fads. The purpose of smart WMS is to decrease the danger of a lack of products that are in demand.

The Basic Principles Of Omaha Warehouse

Certainly, it is a technique to distribute to start with the oldest items in the supply and LIFO technique, which is last-in, a first-out strategy that states that one of the most recent products ahead are the first to leave. WMS likewise has a feature to integrate information with ERP that adds to acknowledging and also updating stock information as well as dispersing it across venture departments to make much better choices on sales.Although these advancements just start to appear on the WMS software advancement market, they provide superb hands as well as eyes-free modern technologies that improve working capability each time. Updated details on orders, suppliers, clients, as well as you could try this out returns, order handling documents is an essential in warehouse management. Information on orders ought to be transferred efficiently and transparently.

Report this wiki page